This week got to play with 3D scanning and 3D printing. First we will check 3D scanning.

Scanner used was Shining 3D EinZweiDreiScan-SocialEdition.

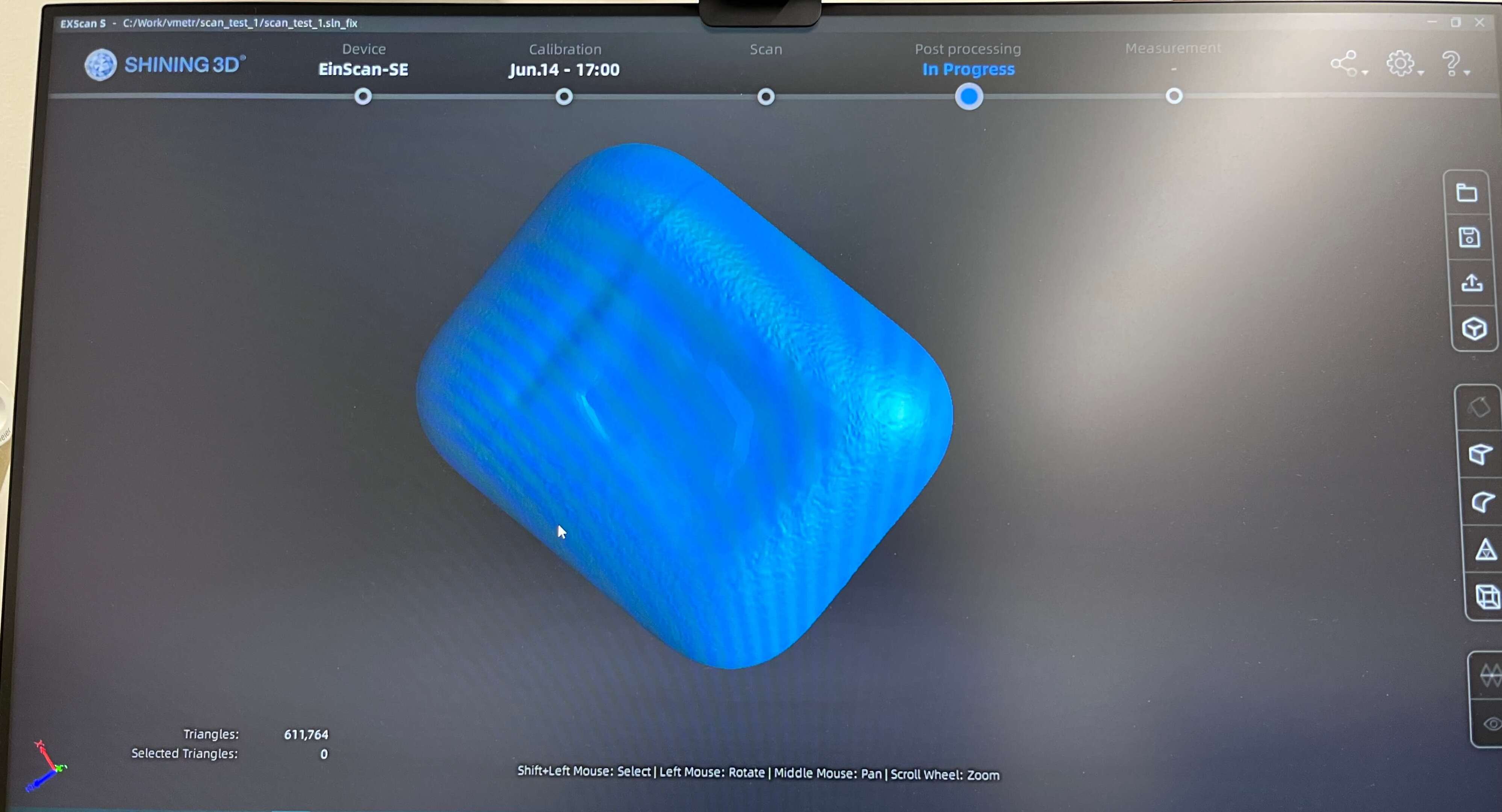

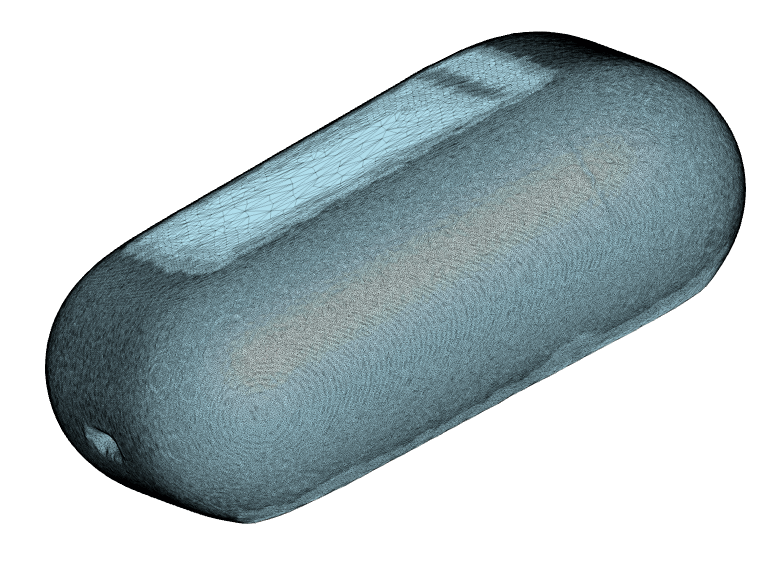

First thing i tried scanning was my airpods case. We start by calibrating the scanner using flat plastic with pattern of circles.

Then we place our item on it and we can start scanning.

Some things to note:

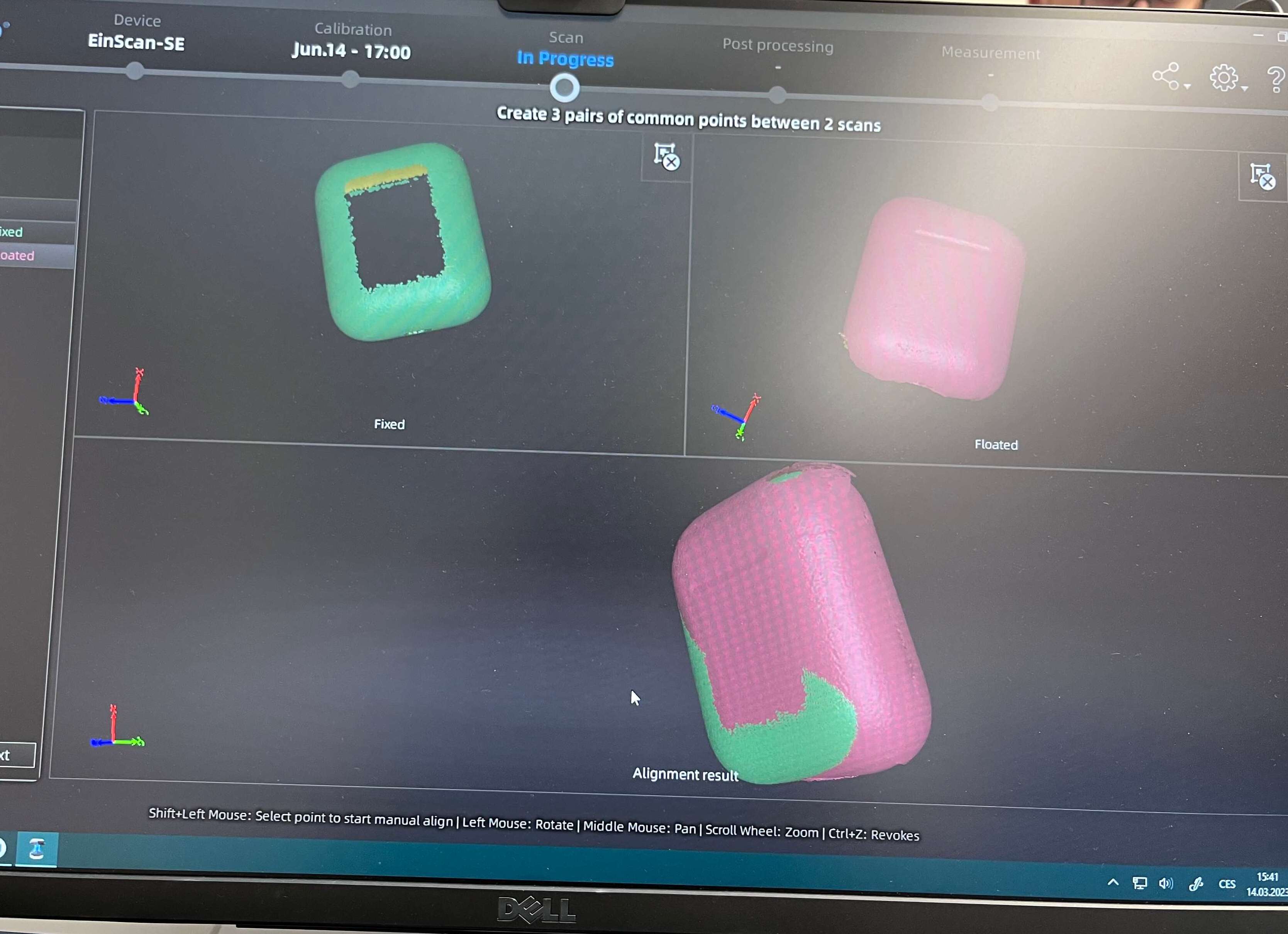

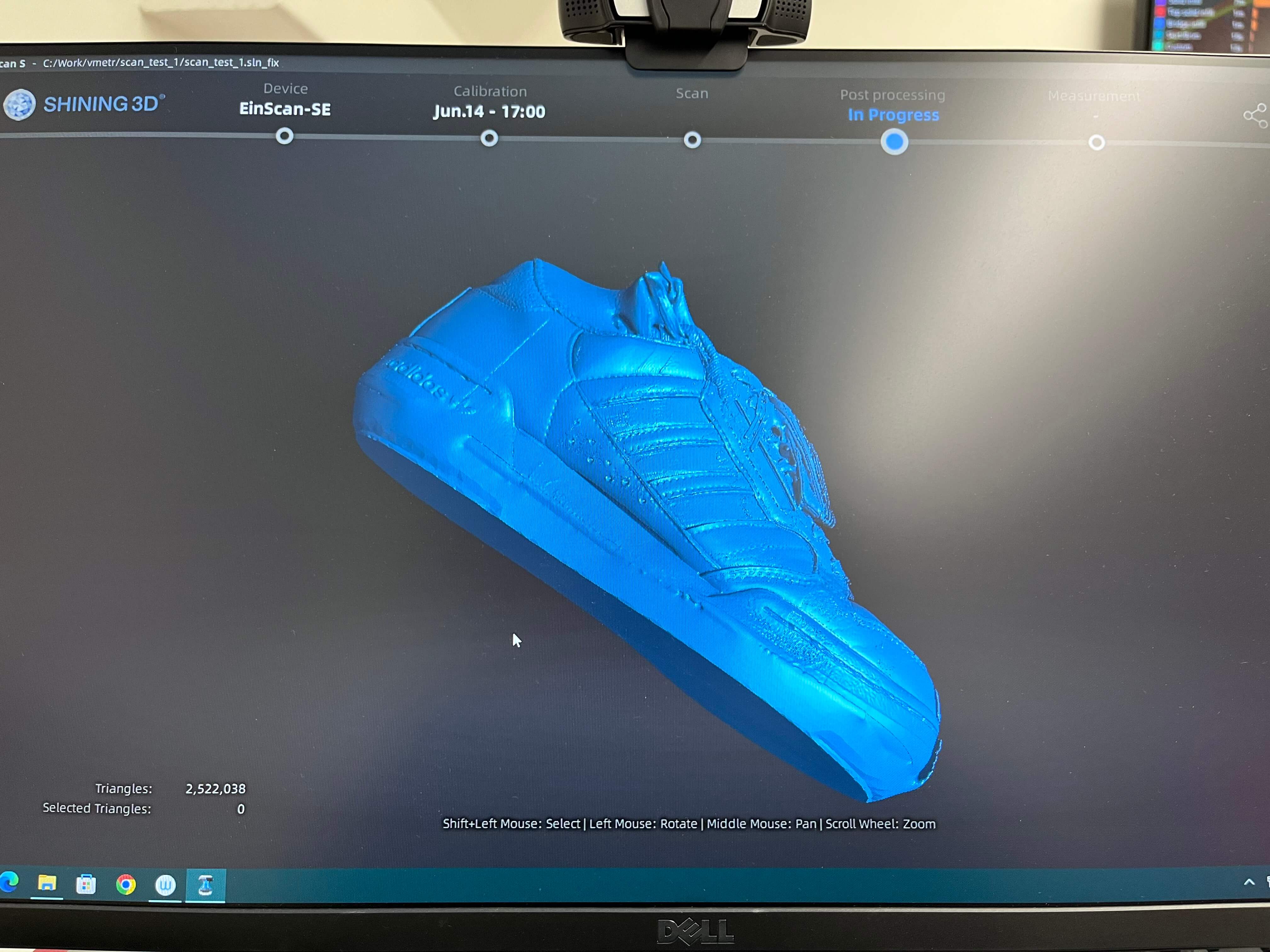

Next i tried scanning my shoe. This scan was composed of multiple smaller scans, becouse the shoe could not fit on the plate. I also needed to align the heel manualy, but otherwise it aligned the scans pretty good unlike in the case of airpod case. Some points were needed to be manually removed too. But the result looks pretty neat!

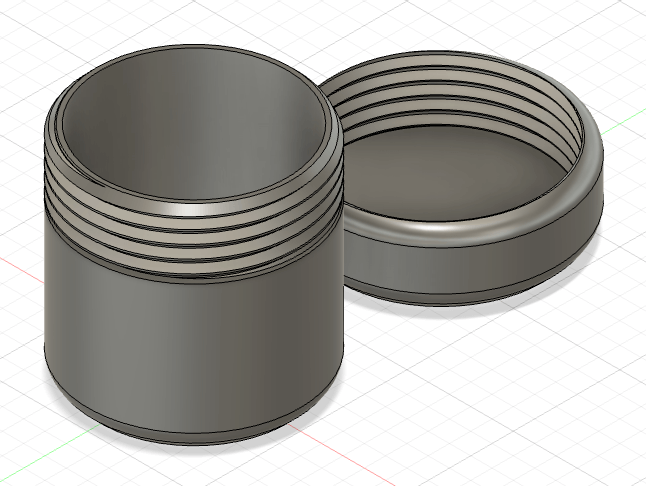

For my 3D print i decided i will design small cup-like container with screw on lid.

Designing screws in Fusion360 is pretty easy but you still need to be concious while doing it.

Although Fusion360 takes some tolerance between two interlocking parts into account, its not enugh for 3D printing it.

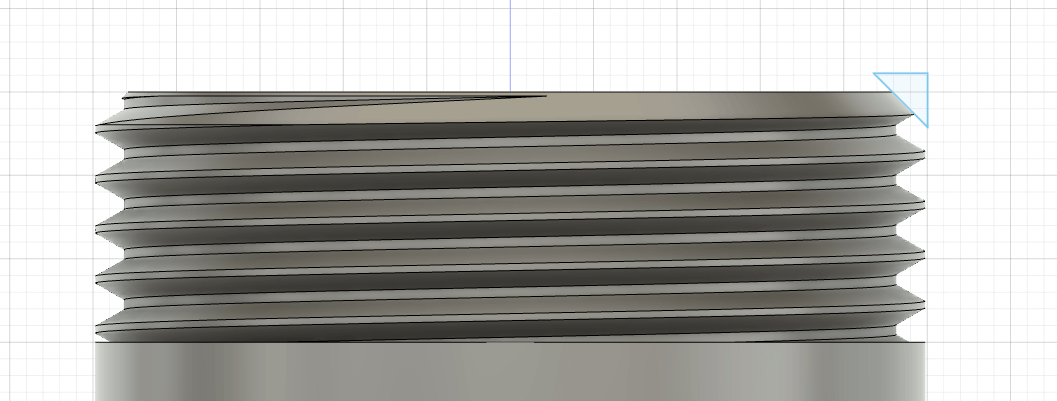

While rounding corners, there shouldn't be overhang steeper than 45 degrees. Steeper angles can't be printed by 3D printer.

Fast and effective printing should be also taken into account when designing parts. For example not making too thick walls which wont make the print stiffer,

the print will only take longer time.

Last trick for designing screws is cutting the top most part of the screw by 45 degree angle, for better fit and easier start of screwing. I also did the same thing for the lid.

This is how it looks 3D printed. It works much better than I imagined.